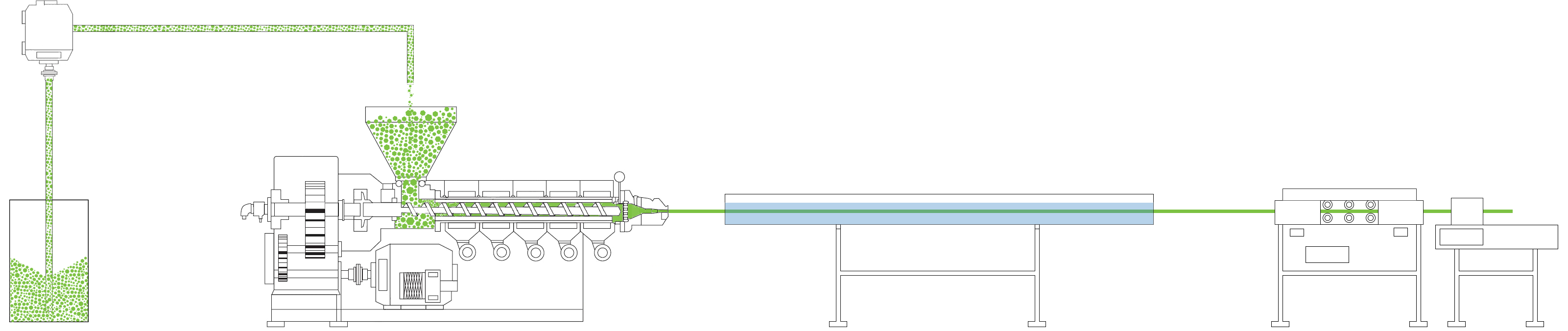

Production LINe

Extrusion is a (thermo) mechanical manufacturing process by which a compressed material is forced to pass through a die to achieve the desired form.

This is how Gainoplast continuously manufactures tubes and profiles.

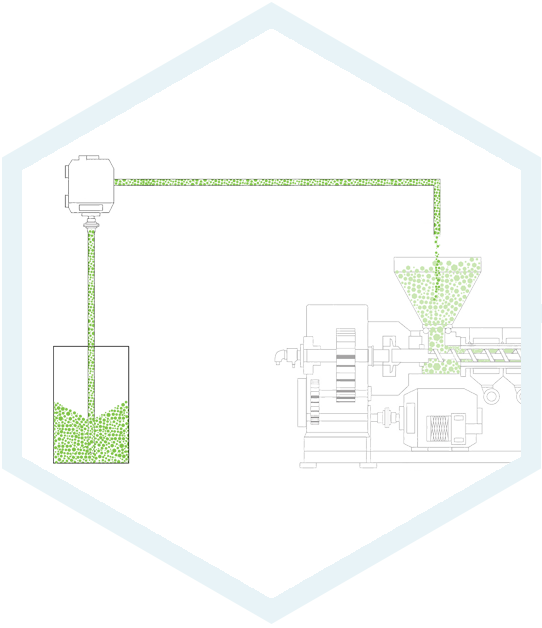

1st step

Vacuuming the raw material towards the extruder.

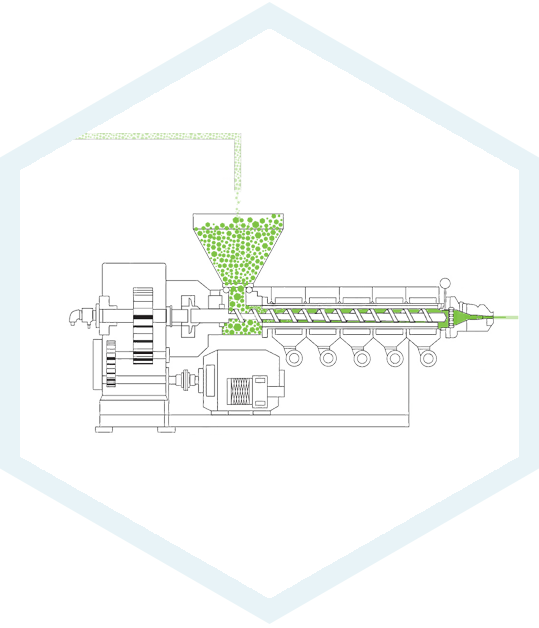

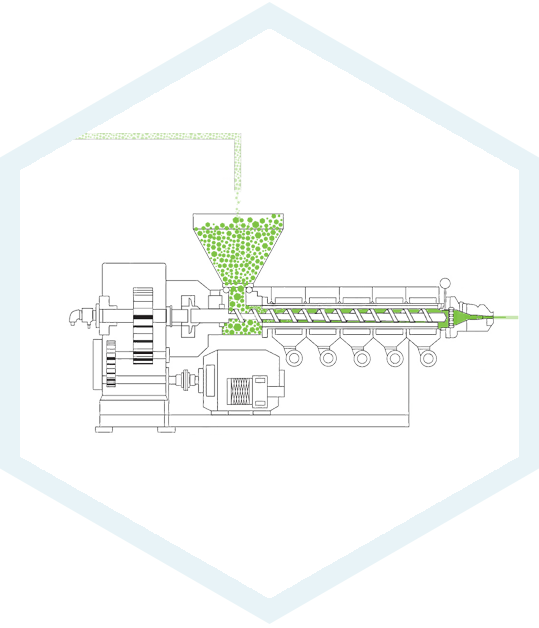

2nd step

The raw material is heated to enter the die.

2nd step

The raw material is heated to enter the die.

3rd step

Once the material is formed after passing through the die, the tube is cooled in a pool at strictly controlled temperature.

4th step

Once the tube / profile is cooled, its internal and external dimensions are checked precisely.

4th step

Once the tube / profile is cooled, its internal and external dimensions are checked precisely.